Our Projects

YK INDUSTRIES is an Engineering Procurement and Construction (EPC) and Technical consulting Company servicing to Water and Wastewater, Air and Energy for Industrial and Environmental sectors. We are leading Manufacturer of Water & Wastewater Treatment Plant and Reject Management plants for “Zero Liquid Discharge” Projects as per local environmental laws.

SCREW PRESS

Screw press consist of: screw conveyor for continuous discharge of sludge, inclined bowl, both moving and stationary discs, variable screw speed and variable torque.

Screw Press is made of a cylinder containing the screw, moving and stationary discs, solid chamber, motor and gear. A strong and self-standing chassis support the working parts, together with flow accessories and safety components. Screw Press has many features to increase the dryness, the solid handling and the cleaning, like: -the power is adjusted automatically to the compression profile, maintaining the required dryness for every changing condition.

SUPPLY & SERVICES

Biological process with MBR plant

Membrane Bioreactors (MBR) combine conventional biological treatment processes with membrane filtration to provide an advanced level of organic and suspended solids removal. When designed accordingly, these systems can also provide an advanced level of nutrient removal. In an MBR system, the membranes are submerged in an aerated biological reactor. The membranes have porosities ranging from 0.035 microns to 0.4 microns which is considered between micro and ultrafiltration.

This level of filtration allows for high quality effluent to be drawn through the membranes and eliminates the sedimentation and filtration processes typically used for wastewater treatment. Because the need for sedimentation is eliminated, the biological process can operate at a much higher mixed liquor concentration. This dramatically reduces the process tankage required and allows many existing plants to be upgraded without adding new tanks. To provide optimal aeration and scour around the membranes, the mixed liquor is typically kept in the 1.0-1.2% solids range, which is 4 times that of a conventional plant.

Continuous stages of RO Membrane filtration up to 90% recovery with reduced operating cost…….

We manufacture a wide range of industrial Reverse Osmosis plants to cater the stringent process requirements. Our industrial RO plants are carefully customized and configured for exclusively textile sectors which is eliminates separated stages of RO I, RO II and RO III. The machine has designed with single Feed pump with High pressure pump and sequential stages can be operated with booster pumps to recover up to 90% with very low power consumption comparatively existing RO plant.

SUPPLY & SERVICES

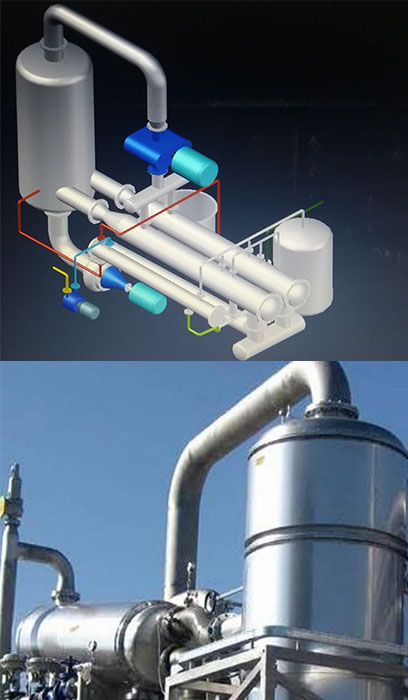

Vapour Compression Evaporation Plant

Vapour compression vacuum evaporator is designed for the efficient treatment of high concentration solution of industrial waste effluent and water treatment plant reject from RO plants with a low energy cost. Its high efficiency is due to the use of a rotary blower which increases its latent heat by the mechanical action of volumetric compression with a small amount of electrical energy used in the motor powering the compressor with very less steam consumption comparatively normal MEE. This heat from the compressed steam is supplied by a heat exchanger to heat the effluent to evaporate and consequently condense the vapour to produce distilled water.

Horizontal Forced circulation evaporators are especially indicated when the flow to be treated contains fouling substances, viscous liquids, crystals or other components preventing natural circulation. This mechanical vapour compression equipment has the least energy consumption and can treat greater flows from 500 LPH to 5000 LPH.

Agitated Thin Film Dryer (ATFD)

Agitated Thin Film Dryer (ATFD) for evaporation of water/solvents to make dry powder or flakes with up to 5% moisture from very high concentrated liquid from MEE. Our standard ATFD has dryer is consist of cylindrical, vertical body with heating jacket and a rotor inside of the shell which is equipped with rows of pendulum blades all over the length of the dryer.

The hinged blades spread the wet feed product in a thin film over the heated surface. A highly agitated bow wave is formed in front of the rotor blades. The turbulence increases as the product passes through the clearance before entering a calming zone situated behind the blades. As the heat will transfer from jacket to main shell under the smooth agitation water/solvent will evaporate and liquid will convert to slurry, to cake and to dry powder or flakes.